A stadium light launched by an Adelaide business last month is set to become a game changer for sporting venues around the world.

The Zenith Gen-V is the world’s smallest, lightest yet most powerful sports luminaire in its class, says Sam Vial, Chief Commercial Officer of advanced technology company and manufacturer VAILO.

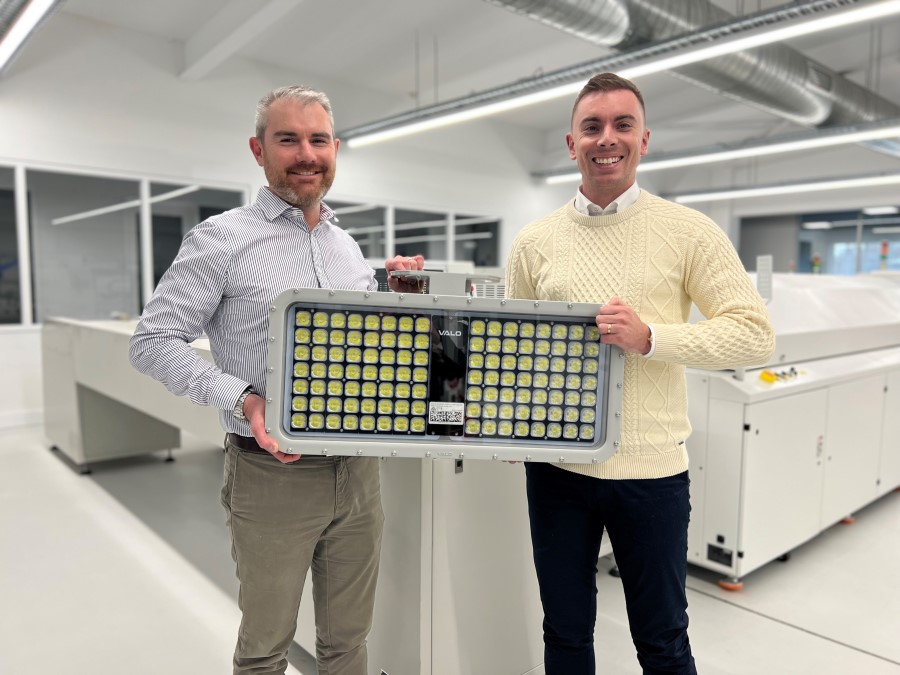

“That may not sound like much until you start to realise that when contractors install a luminaire on to a pole, size and weight matter significantly,” said Mr Vial, pictured (left) with Chief Executive Aaron Hickmann.

“Much of the design and engineering is based on wind loads, and if there is more weight at the very top of a pole and more size, you capture more wind, and in doing so, the pole engineering becomes more substantial and expensive.

“So, by creating something that has the same amount of luminous power as other products on the market but in a significantly reduced package, this gives us a strong advantage.”

The Australian Made-certified Zenith Gen-V, designed and manufactured in Adelaide, is about 30 per cent lighter than similar lights and 10 per cent lighter than its leading competitor.

“Our previous Zenith light was 600 watts and now it’s 1500 watts,” Mr Vial said.

“We’re able to almost triple the output of our previous generation Zenith luminaire by making the product only double the size, which means we’re getting better bang for our buck.”

The power savings are significant.

The lifecycle of a high quality LED is about 100,000-120,000 hours, compared to the more commonly used metal halide stadium light, which produces about 7000 hours of usage before the bulb needs to be replaced.

“If you have to replace the bulb and it’s 50m up in the air, the associated costs are significant,” Mr Vial said.

“You’ve got crane hire, trained staff with Working At Heights certification and potential downtime to the oval or stadium, including possible turf damage from the crane. Changing bulbs is both complex and costly.

“LEDs dramatically reduce that need. In a lot of cases for many clubs, the poles have generally been there for quite a long time and are probably getting to the end of their service of life.

“In those circumstances, the poles will need to be replaced, as well.”

LEDs also give clubs flexibility with how they use their lights.

“With traditional metal halide lamps used at most stadiums, the lights are either on or off,” Mr Vial said.

“It’s 100 per cent or 0 per cent. Plus, those lights generally take about 10-15 mins to warm up.

“LEDs enable you to dim the output of the light which directly reduces the amount of power you use. You can dim it all the way down to half a per cent and all the way up to 100 per cent.

“If you’re doing sports training, you can turn the lights down and everyone can still practise safely. It’s only for televised matches that stadiums need to power up the lights to 100 per cent.”

Stadiums will see a huge ROI for twilight games, Mr Vial said.

“They can put light sensors around the oval and tune the power output based on what the light measurements say, rather than turning it on and letting it run when the sun’s out; they can just have a bit of infill lighting instead.”

For sporting clubs, the technology brings economic and safety benefits.

“There’s a huge focus on increasing women’s participation rates in all sports and making sporting grounds safer at night,” Mr Vial said.

“With this in mind, we’re looking at ways of setting up a tiered lighting control solution at clubs for remote operation that would give defined users controlled access to different levels of light output.”

Interest in the Zenith Gen-V is already high, with VALO in talks with many clubs looking to upgrade their lighting.

“By offering a high quality, locally manufactured product with a 10-year warranty, we can compete with the pricing of the quality end of the importers,” Mr Vial said.

“There may be cheaper products out there, but the quality is not always what it seems.”

It is an exciting time for VAILO, which is growing rapidly in anticipation of a hungry market.

“Early last year, we didn’t have any engineering resources here on site,” Mr Vial said.

“We didn’t have a manufacturing setup. We had nothing. So, basically, from July last year until now, we’ve had to create a team, grow the team, audit and nominate our suppliers, work out the contract engineering that we needed, create a manufacturing facility and get the product tested, validated and certified.

“All of that has been done in the past 12 months. It’s been an amazing challenge and outcome for the team to do what they have done in such a small amount of time.”

During that time, the team has grown from four to 16, with three ads out on the market.

“If we get anywhere close to hitting the target numbers that we think we are going to achieve, we’re going to be a team of close to 60 by the end of next year,” Mr Vial said.

The company is also shaking up the market in terms of lead time.

“At the moment, if someone wants to order a high-end sporting luminaire, the lead time is about 18 to 20 weeks — almost half a year,” Mr Vial said.

“What we are doing is buying in all the component stock, holding it and building to order. So, we’re transforming that component stock to finished goods only when we need to, which gives us an excellent advantage. It means we can respond to customers’ requirements a lot faster.

“We’ve already got some significant orders, some of which will be 2022, which is exciting.”

The lighting partner for organisations including Sports SA, Vicsport, Sport NSW, Hawthorn Football Club, Adelaide Crows, Adelaide United and Football Federation South Australia, VALO sees huge potential for the Zenith Gen-V in the US, where Australian-made products are looked upon favorably.

“Our goal is to get installations done here, build up case studies, then move into the US market as quickly as we can,” Mr Vial said.

“The first install will be a key moment. To create a high-powered output product and then control that light to project only where you want it, that’s really hard. We think we’ve done a good job of that in our Zenith Gen-V.”

VAILO has been a member of Ai Group since May 2022.

“As a business new to manufacturing in Australia, we chose to join Ai Group after seeing the support other manufacturers received throughout the Covid-19 pandemic. It is crucial to have a peak industry group representing the interests of companies like VALO, and we are pleased to already see value provided to us so early on.” — Penelope Bettison, Chief Operating Officer, VALO

Wendy Larter is Communications Manager at the Australian Industry Group. She has more than 20 years’ experience as a reporter, features writer, contributor and sub-editor for newspapers and magazines including The Courier-Mail in Brisbane and Metro, the News of the World, The Times and Elle in the UK.