Everyone has their own COVID-19 story to tell.

But an innovative manufacturer in South Australia has a pandemic tale like no other: a life-or-death race against time to triple its production of a crucial and highly specialised component for lifesaving medical equipment.

With ingenuity, determination and commitment, Adelaide-based Key Tubing & Electrical rose to the challenge.

It was during the height of the pandemic when the component manufacturer was asked to ramp up its production of a bespoke heater cable from 3 million metres a month to 9 million.

The component — a fine wire the width of kitchen string — is a key part of its client’s ventilators and respirators, which also spiked in demand owing to COVID.

The solution seemed straightforward: ask the German manufacturer of the machine that Key uses to make the cable to send more machines.

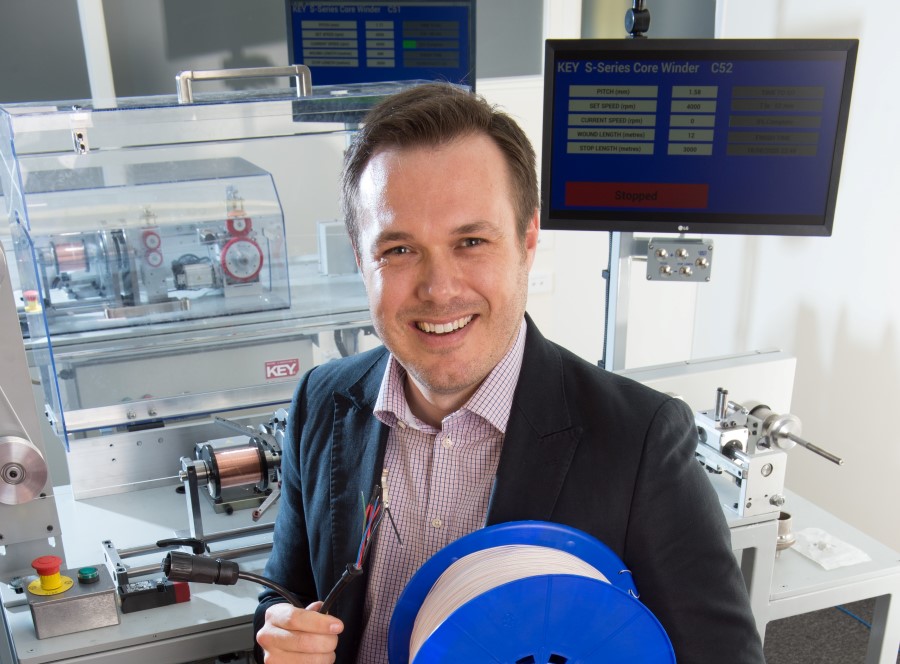

But the request could not be fulfilled, Commercial Director Henri Hugo, pictured, recalls.

“We needed 30 machines, but they could only commit to giving us one machine every three months,” Mr Hugo said.

“We were flabbergasted. We thought ‘what will we do?' It was a really serious problem. No one else in the Asia Pacific region makes this component and our capacity could have potentially held back millions of devices getting out into the market.

“We had no option but to somehow make the machines ourselves. We couldn't say no. It was more than letting down our customer; it was a much bigger picture.

“All of a sudden, this tiny company in Adelaide was a key piece in the difference between millions of people getting life-saving therapy or not.”

Mr Hugo credits Key’s R&D capabilities for being able to rise to the challenge within the high-pressure context of a pandemic.

A company built on innovation, Key has long learned to pivot and diversify.

When demand from its prime market – the refrigeration industry – wound back in the 1990s, the business turned to other industries including beverage systems, air conditioning, after-market automotive, caravans and, of course, medical products.

“When we started making medical-grade heater cable for our client 20 years ago, we tried to use our own machines that were making the heater cable for fridges, but they weren’t high-tech enough,” Mr Hugo said.

“So, we ended up buying a bunch of machines from Germany, which we then modified.”

The COVID-19-related spike in demand for the heater cable, coupled with the limited supply of machines from Germany, meant Key had to revisit its own, original machine and try to improve its design.

It took four months to perfect, with Head of Engineering Tony Smith leading the charge.

“The machines that make this medical-grade cable are highly tuned and difficult to make,” Mr Hugo said.

“We had an idea of how we wanted to do it, but it wasn’t working the way we thought it would and because we had to make so many machines in such a short amount of time, we had to start building them without a final design.

“We finished one machine completely, tuned that up and then applied that to the rest of the 30 units. So, as we developed one, we said ‘that’s a good idea, we’ll put that in the rest of them’.

Tweaking the machines to expand capacity and ramping up overtime meant Key could fulfill the seemingly impossible request to triple production.

“We had to make it work,” Mr Hugo said.

“If we didn’t somehow build these extremely complex machines, people were going to die. It was a difficult time. Not only were we experiencing the fear of this pandemic that was spreading around the world, we were suddenly right in the middle of it because at that time, everyone was calling out for respirators and ventilators.

“We also had the constant threat of possible COVID-related shutdowns looming over us.

“For all those reasons, fulfilling our client’s request was a real career highlight for a lot of people here, and the dedication of our staff was inspiring.

“To date, we haven’t missed any production deadlines. It was a real feat.”

The challenge has helped Key – which was established 70 years ago and has a staff of around 70 – to improve its capacity and efficiency with overtime no longer needed.

“As a company, we enjoy taking on challenging projects,” Mr Hugo said.

“We don’t chase the easy stuff. When companies come to us, asking ‘can you do this?’, it means they can’t find it anywhere else.

“What makes us different to some other manufacturers is that we have kept our IP (intellectual property) capacity.

We’re not just people who have machines that pump stuff out. We’ve got an R&D team, we’ve got engineers and we’ve got toolmakers.

We’re also very vertically integrated and try to capture as many steps in the value chain as we can.

“We’ve kept this capability within our company so that we can respond to challenges. It’s important for Australian manufacturing that this ability lives on.

“You’ve got to keep innovating and doing something different.”

Key Tubing & Electrical has been a member of Ai Group since 2018.

“The Australian Industry Group has been a tremendous support for our business over many years. Being able to get in touch with a number of experts, especially in HR, has been vital. We can be assured we are getting the best advice without burdening our overheads. Additionally, for medium-sized businesses like us, operating in today’s changing business landscape is especially challenging as staying up to date can consume valuable resources. However, Ai Group has been on the front foot in many critical areas, and we have relied on their advice throughout the COVID-19 pandemic.” — Henri Hugo, Commercial Director, Key Tubing & Electrical.

Wendy Larter is Communications Manager at the Australian Industry Group. She has more than 20 years’ experience as a reporter, features writer, contributor and sub-editor for newspapers and magazines including The Courier-Mail in Brisbane and Metro, the News of the World, The Times and Elle in the UK.