The future of bathrooms is smart.

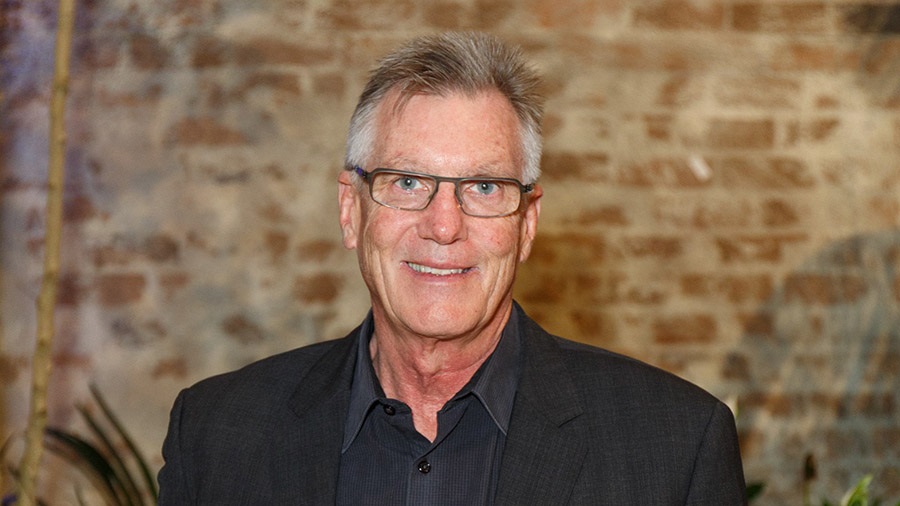

Waking up to a shower pre-set to your ideal temperature, checking your water usage of the tapware on a smartphone and saving water are just some of the water conservation measures and user benefits households can look forward to, says Dr Steve Cummings, Chair of Ai Group’s Water and Plumbing Products Cluster and Director Innovation at GWA Group.

“Smart bathroom technology will allow you to do all these things and a lot more,” Dr Cummings said.

“We have been focusing on the commercial area, but definitely smart bathrooms will also move into the domestic area. We have already had interest in it.”

Not surprisingly, COVID-19 is behind the increased interest from the commercial sector in the smart bathroom ecosystem concept Dr Cummings began creating eight years ago that is now named “Caroma Smart Command”.

“With COVID, where possible, everything should be no-touch in a commercial bathroom,” Dr Cummings said.

“I developed this as a complete bathroom concept and it’s pleasing that we now have a whole ecosystem of no-touch products that can communicate with a cloud or a BMS (building management system). Data in from the BMS allows the building manager to review water usage data and alerts, together with other important information from the products and take action as required remotely in real time. A building manager or a plumber can set up the system in the bathroom with a smartphone where data can also be reviewed at the individual bathroom level. Importantly, data is supplied on how much water the ecosystem uses so that management actions can be taken to achieve optimum levels of water efficiency in a building.

“Back then, this was conceived for a different reason. Although, I knew that for hygiene, it was a good thing to have every bathroom product you need to use to be touch-free in operation – this was always a focus for me through the development.

“You do not like to go into commercial bathrooms and touch tapware, urinal and toilet buttons to use the fittings – or even open a cubical door."

Dr Cummings said he was working on the potential of a smart water systems eight years ago.

“We were talking then to leading electronic experts in the field and asked, ‘what do you think about this concept?’” he said.

“They said: ‘Do you know you are doing IoT?’ While this was pleasing to hear, I knew we had a massive challenge in front of us.

"However, it was great that we were actually doing it. We were making bathroom products very smart. The products could communicate and provide data from an ecosystem of products and systems and other sophisticated capabilities. I had some previous electronics experience, but this was going right into the deep end. However, I knew what I wanted to do. It mainly involved putting the right team together, supported by the necessary resources to do it.

“A water-saving feature in the ecosystem that is very important to me is the capability of an electronic smart shower that pre-warms the water to the user’s selected temperature and diverts the water away from the shower until the selected temperature is achieved.

“This saves water that would normally be wasted down the shower drain and can save about six litres per shower. It’s been a big journey for me.”

Internationally renowned, multiple award-winning Dr Cummings has always been ahead of the game.

Among his many achievements, he was responsible for designing the world's first two-button, dual-flush ceramic cistern called the Viceroy.

“In the early 1980s, I was a member of the original Caroma R&D team that developed the two-button, dual-flush technology,” Dr Cummings said.

“I became R&D manager for vitreous china when I moved to Caroma, where I continued my work on a two-button, dual-flush vitreous cistern together with my colleague, who was working on a plastic dual-flush version.

“Two-button, dual-flush started off in Australia and went industry-wide, becoming the standard across the industry and is now used across the world. It was not an easy pathway to start and to make it happen. These things don’t come easy. Nothing’s easy in this field.”

Sustainability and saving water are at the forefront of all Dr Cummings’ developments.

“The progressive reduction in flush volume technology to 4.5/3L flush volumes has got us to a point where we’re saving about 70% of water in Australia compared to the original 11-litre, full-flush cisterns that were around twice the size of the current models,” Dr Cummings said.

“Seventy per cent is more than 100,000 Olympic swimming pool every year. That’s probably the thing that I really like the most. I’ve been able to contribute to water conservation in Australia to benefit the environment and consumers in reduction of water usage costs."

His impact is international.

“On the standards side of my career, it was a great honour to become Chair of ISO 316 Water Efficient - product rating, which is an international water efficiency labelling standard that is now nearing completion," Dr Cummings said.

“In the initial meeting in July 2018, it became clear a new flexible approach for the development and drafting of the standard was required. This approach was adopted by the committee and was found to be critical to allow for the requirements of participating countries, most with varying national standards and water efficiency labelling schemes/programs, in achieving consensus within the required timeline. Throughout the development of ISO PC 316, a key focus has been to provide the criteria for developing countries to establish an effective water efficiency labelling standard that will save water resources.

“I am very pleased, personally, that the committee has developed and completed the draft that, when published, will provide developing countries and others with the means to produce their own Water Efficiency Labelling and Standards (WELS) programs. This will allow their populations to benefit from their choices to identify and select more water-efficient products, as we can do in Australia, along with other developed countries around the world.

“Here in Australia, if you purchase a toilet or a tap, they must be WELS-labelled, showing their star ratings identifying their water efficiency. This allows the purchaser to make an informed selection on the efficiency of the product.”

Reducing lead content in tapware is next on the agenda.

“It’s not water conservation but it is improving the health of Australians,” Dr Cummings said.

“So, the water we drink in the future will have lower levels of lead in it.

“In everything I do, I think of how I could make products better and more efficient. It’s a lifelong journey for me. I work closely with a team of innovation engineers who I like to think are also taking up my passion for sustainability and smart technologies."

“If you haven’t got the passion, then you haven’t got the drive to do this type of sustainability innovation work.”

Ai Group's Standards and Regulatory Services team has a member engagement in standards development of more than 280 people on 400 technical committees. Members value the opportunity to influence the development of technical documents often called into regulation that impact their products. Dr Steve Cummings chairs Ai Group’s Water and Plumbing Products Cluster and is actively involved in standards development across the sector. He is famous for the statement: “I have seen situations where the way just one word in a standard is interpreted can have very significant ramifications for industry”.

Wendy Larter is Communications Manager at the Australian Industry Group. She has more than 20 years’ experience as a reporter, features writer, contributor and sub-editor for newspapers and magazines including The Courier-Mail in Brisbane and Metro, the News of the World, The Times and Elle in the UK.